Introduction

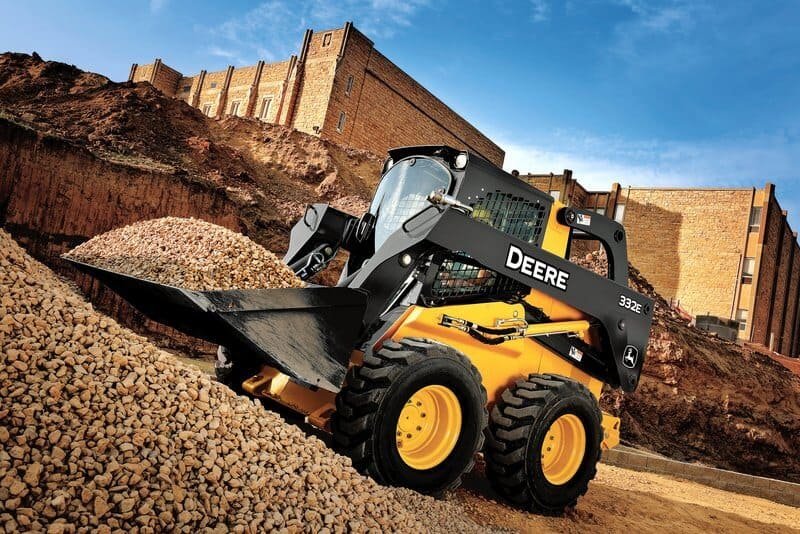

Traditionally, skid steer machines are tracked or wheeled machines with front and rear wheels. All the wheels are mechanically connected to rotate simultaneously. These loaders are designed keeping performance, longevity, and operator comfort in mind. In the construction sector, the usage of a skid steer machine has increased significantly.

Numerous operators and companies employ compact track loaders regularly to accomplish landscaping and construction tasks. Skid loaders are lighter in weight, which means they are faster and more nimble. With various skid steer attachments, skid steers have become extremely versatile. We can utilize them for a variety of purposes.

They have also emerged as an integral part of modern farming. The small size, easy handling, and robust engine have made them indispensable for the routine tasks of farming. However, unique maintenance issues must be addressed when utilized in the agricultural sector. If you are using them, you must be aware of how crucial it is to maintain their quality.

There are a few signs that can indicate that there are some issues with a radial lift loader. Timely detection of these issues can prevent productivity losses and expensive repairs. Recognizing these signs can help you effectively evaluate and care for your radial lift machines.

Engine Issues Of Skid Steer machine

The fuel system is often the source of engine starting problems in a skid steer machine. Each component of the skid steer’s fuel system must be inspected separately, typically including filters, fuel lines, and a tank. Skid steers can have problems if their filters aren’t changed on time. To prevent engine failure, vertical lift machines operating in dusty environments will require frequent filter replacements.

The diesel fuel tank should be inspected once the filters have been serviced in the skid steer machine. When fuel cannot flow from the tank to the fuel injector, the engine’s performance may be compromised. We ensure that the fuel injectors are not blocked with debris because they cause improper fuel flow.

When a skid steer machine’s glow plugs are not functioning properly, there could be an issue with the engine. Glow plugs warm a skid steer’s combustion chambers in cold weather, allowing the engine to work properly. These glow plugs can sometimes become loose and don’t prevent the engine from warming the engine. Checking engine plugs’ tightness is crucial to avoid engine dysfunction.

Finally, double-check that the throttle cable is properly connected to the engine’s throttle body. Cables might fall free, causing the engine to malfunction. To determine the security of these cables, examine cable’s both sides. The cables must be connected to the throttle body, which is typically located at the top front of the motor, and the accelerator.

Hydraulic Issues Of Skid Loader

The hydraulic system is also a common cause of small-frame skid steers problems. Change in hydraulic fluid levels from the rated level often results in malfunction. Hydraulic systems work best with the manufacturer-recommended fluid level. Pumps of the hydraulic system are also essential to the skid steer’s operation. Check the belts if it’s a belt-driven model and doesn’t operate.

They can have a considerable impact on the functioning of the hydraulic system if they are worn or lost. Checking for loose fittings and hydraulic line leaks is very necessary because these factors can significantly reduce the efficiency of the hydraulic system.

Before examining these factors, you must push the hydraulic system and verify the engine and pump are running. When the fluid in the system is under pressure, it will be much easier to detect any pinhole leaks. Ensure that you are wearing gloves & safety goggles during this inspection to prevent injury from the high pressure.

After checking for leakage, you can inspect the control valve’s fittings and seals of the skid loader. Damage to these seals or loose fittings will reduce the efficiency of the hydraulic system of the wheel loader. Make sure the valves open as well as close without any resistance in your skid steer machine.

Control System Issues

There are situations in which operators discover that the joystick is not responding to their directional inputs. Loose steering or loading connections might cause these troubles, so reconnect or tighten these. You should check the wires attached to the skid loader joystick and ensure that they are attached correctly.

The wires connect the actuators and the hydraulic pump. If you are unable to tackle by alternative methods, you should replace the circuit board that controls the joystick. There are possible problems with the control system. It implies that the control system on your device responds slowly.

You should inspect the safety switches on the skid steer and check the connections mentioned above. If safety switches fail to function properly, the control system will likely experience problems as a result. These switches should work and provide secure connections. Bad circuits might also impair your control system. Therefore, inspecting the skid steer’s batteries for any discharge is vital.

Airborne Debris

Skid loaders are subjected to airborne particles like chaff, silage, and grain dust on farms. This can rapidly accumulate on the radiator as well as oil cooler screen surfaces. If the engine is not cleaned periodically, it may cause overheating. You may need to inspect and replace your skid steer’s filters more frequently.

Like if you are working in an area with a lot of this kind of waste, you should replace filters as early as possible. This airborne dirt and debris can also wreak havoc on your skid steer’s electrical connections. This issue is best addressed by using compressed air instead of water to remove dust from these connections.

Corrosion

Corrosion is another major issue for a skid loader in agricultural farming. Water will always act as a corrosive agent. Nevertheless, fertilizer is also corrosive. A simple way to reduce corrosion caused by fertilizer exposure is to repeatedly clean the equipment so that the fertilizer does not accumulate.

In addition, new tools can be treated with rust-preventative measures to drastically cut down on the likelihood of corrosion. Remember that some skid steer machine repairs are useful and that corrosion prevention is still an option for damaged equipment.

Cleaning

We have discussed cleaning as a component of addressing airborne dust and corrosion in the skid loader. However, its significance cannot be overstated. A pressure washer must wash your skid steer to scrub away the contaminations. The contamination might accelerate wear, so removing potentially corrosive substances such as fertilizer is essential.

The main seal of the drive motor gets dislodged and rendered ineffective due to the accumulation of dried material. If there’s dust accumulating around certain parts that shouldn’t get wet, you must blow it away with compressed air. Remember that a clean skid steer makes it easier to detect issues. Fixing issues early saves time and money.

Skid Steer Lacks Power

A blocked hydraulic fuel filter may potentially create significant performance concerns with the skid steer. For instance, if you observe that your loader has less power, the fluid filter might be clogged. A blocked filter impedes fluid’s free flow, reducing the loader’s efficiency.

More power is required to overcome when friction is excessive, giving the impression that the end drive is weak. Tracked equipment might experience excessive friction due to elevated track chain tension and worn rollers and idlers.

Excessive Noise or Vibration

A sign of bearing wear is excessive noise or vibration coming from your hydraulic motor. Bearing wear can cause expensive repairs to your hydraulic motor’s internal components. Don’t put the pieces back together after the metal has been chewed up; this kind of damage is irreparable.

The hydraulic motor should be serviced if you or a worker detects unusually high vibration and noise levels. You shouldn’t fix the problem until you have to entirely replace the final drive motor due to wear and tear.

Leaks

If the hydraulic motor on your skid steer is spilling fluid, the seals or bearings may be at fault. The consequences of their failure could snowball if just one of them were to go down. A hydraulic motor will be destroyed and will need to be replaced as a result.

Check for leaks regularly by visually inspecting the area. After that, as soon as you notice a leak, have it fixed. Leaks not only let vital liquids escape, but also they may let in harmful contaminants like dirt, sand, and grit.

Final Thoughts

Despite the fact that they are fantastic tools to have, they don’t always have an ideal operational environment to work in. Working conditions that are too rough for a skid steer increase the likelihood of breakdowns. Increased chances of corrosion and dust accumulation are common issues with skid steers.

This is why it’s crucial to maintain the functionality of the skid steers. Performing checks before buying or renting a skid loader will ensure that it works perfectly. You must always look for the best skid steer machine manufacturer to get a reliable machine.