Introduction

China Skid Steer Loaders are versatile machines that can perform a wide range of tasks in construction, agriculture, and other industries. However, like any heavy equipment, they require regular maintenance to operate at their best. Regular maintenance helps ensure the safety of the operator, extends the lifespan of the machine, improves its performance, and reduces operating costs.

This blog will explore the benefits of regular maintenance for China Skid Steer Loaders, provide a maintenance checklist, discuss common maintenance issues, and offer tips on how to conduct regular maintenance. Whether you hire a professional or do it in-house, regular maintenance is crucial for the longevity and efficient operation of your skid steer loader.

Benefits of Regular Maintenance

Regular maintenance is essential for any machinery to function optimally, and China Skid Steer Loaders are no exception. These machines are used in various industries, such as construction, agriculture, and landscaping, and require proper maintenance to ensure their safety, longevity, and performance.

A. Improved safety

One of the most significant benefits of regular maintenance is improved safety. China Skid Steer Loaders can be dangerous when not properly maintained, leading to accidents that can result in severe injuries or even fatalities.

Regular maintenance tasks such as checking and replacing faulty brakes, inspecting and replacing worn-out tires, and testing the machine’s safety features can significantly reduce the risk of accidents. Routine maintenance can also prevent the buildup of debris or dirt that can impede visibility, leading to accidents.

B. Increased lifespan

Another benefit of regular maintenance for China Skid Steer Loaders is increased lifespan. These machines are expensive investments, and it is essential to protect them to ensure that they last for as long as possible.

Routine maintenance tasks such as changing the oil, replacing filters, and lubricating moving parts can extend the machine’s life by preventing premature wear and tear. When properly maintained, a skid steer loader can serve for many years, providing value for money.

C. Improved performance

Regular maintenance can also improve the performance of a skid steer loader. Over time, parts of the machine can become worn or damaged, leading to reduced efficiency and output. Regular maintenance tasks such as cleaning and tuning the engine, inspecting the hydraulic system, and checking the electrical system can improve the machine’s performance, making it more reliable and efficient.

D. Lower operating costs

Finally, regular maintenance can lead to lower operating costs. Neglecting maintenance can lead to costly repairs or replacements of parts that could have been avoided with routine maintenance.

By investing in regular maintenance, operators can identify and address issues early on, preventing them from escalating into more significant problems that require expensive repairs. In the long run, this can save money on operating costs and reduce downtime, increasing productivity.

Maintenance Checklist

Maintenance is a critical aspect of owning and operating China Skid Steer Loaders. Regular maintenance helps to extend the lifespan of the equipment, improve performance, reduce operating costs, and enhance safety. A comprehensive maintenance checklist should include daily, weekly, monthly, and annual tasks to ensure that the skid steer loader remains in optimal condition.

A. Daily maintenance tasks

Daily maintenance tasks involve conducting a visual inspection of the skid steer loader before operation. This includes checking the engine oil level, fuel level, hydraulic oil level, coolant level, tire pressure, and any leaks.

The operator should also inspect the engine air cleaner, hydraulic oil filter, and fuel filter for any debris or signs of wear. Additionally, they should clean the loader of any dirt or debris that may have accumulated during the previous operation.

B. Weekly maintenance tasks

Weekly maintenance tasks include checking the skid steer loader for any loose or damaged components such as hoses, belts, and bolts. The operator should also check the tire tread depth and inspect the brake system for any signs of wear or damage.

Additionally, they should lubricate any moving parts such as the lift arm pivot points, tilt cylinder pivot points, and drive chain.

C. Monthly maintenance tasks

Weekly maintenance tasks include checking the skid steer loader for any loose or damaged components such as hoses, belts, and bolts. The operator should also check the tire tread depth and inspect the brake system for any signs of wear or damage.

Additionally, they should lubricate any moving parts such as the lift arm pivot points, tilt cylinder pivot points, and drive chain.

D. Annual maintenance tasks

Annual maintenance tasks include replacing the engine air cleaner element, fuel filter, and engine oil filter. The operator should also inspect the exhaust system for any signs of corrosion or leaks, and replace the hydraulic oil and engine coolant. Additionally, they should inspect the drive belt for any signs of wear or cracking, and replace the track tensioner grease.

Common Maintenance Issues

China Skid Steer Loaders are heavy-duty machines that can endure a lot of wear and tear in their daily operations. However, like any other equipment, they are subject to wear and tear and maintenance issues that require attention to keep them running optimally.

A. Overheating

Overheating is a common issue with China Skid Steer Loaders. It can occur due to several reasons, such as insufficient coolant or oil, a clogged or dirty radiator, or a malfunctioning cooling system. When a skid steer loader overheats, it can lead to significant damage to the engine and other critical components.

Operators should regularly check the coolant and oil levels and inspect the radiator to ensure that it is clean and free from debris. In case of overheating, it is advisable to turn off the machine and allow it to cool down before investigating further.

B. Hydraulic leaks

Hydraulic leaks can occur due to various reasons, such as damaged seals, worn hoses, or loose fittings. Hydraulic leaks can lead to reduced performance, inefficient operation, and even safety hazards.

Operators should inspect the hydraulic system regularly to detect any leaks and repair them promptly. It is advisable to replace damaged seals and hoses, tighten loose fittings, and regularly clean and lubricate the hydraulic system.

C. Electrical problems

China Skid Steer Loaders rely on an electrical system to operate, and any malfunction can cause significant downtime. Electrical issues can be caused by damaged wiring, loose connections, or a faulty battery.

Operators should regularly inspect the electrical system to detect any issues and replace or repair any damaged components. It is also advisable to regularly check the battery and replace it when necessary.

D. Tire wear and tear

China Skid Steer Loaders are equipped with heavy-duty tires that can withstand significant loads and rough terrains. However, like any other tire, they are subject to wear and tear, which can cause safety hazards and reduced performance.

Operators should regularly inspect the tires for any signs of wear and replace them when necessary. It is also advisable to maintain proper tire pressure and avoid operating the skid steer loader on rough terrains.

How to Conduct Regular Maintenance Of Your China Skid Steer Loaders?

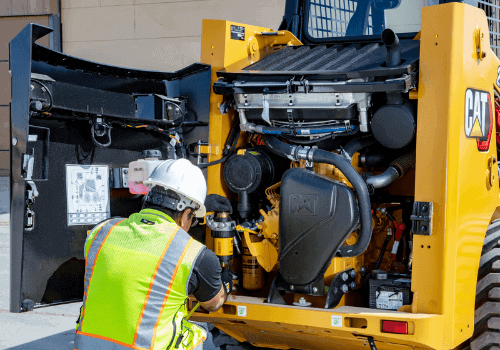

China Skid Steer Loaders are heavy-duty machines that require regular maintenance to ensure they perform at optimal levels. Conducting regular maintenance on these machines can be done in two ways, by hiring a professional or conducting maintenance in-house. Both approaches have their benefits and drawbacks, and choosing the right method depends on several factors.

A. Hire a professional

Hiring a professional is the most convenient approach for conducting regular maintenance on China Skid Steer Loaders. This is because professionals have the experience, skills, and tools needed to diagnose and repair any issues with the machine. Hiring a professional can also save time and effort, as they can quickly identify any issues and take the necessary steps to fix them.

However, hiring a professional can be costly, especially if maintenance is required frequently. Additionally, scheduling maintenance may not always be convenient, as professionals may have a backlog of appointments, which may lead to delays.

B. Conduct maintenance in-house

Conducting maintenance in-house is another option for maintaining China Skid Steer Loaders. This involves training personnel in the necessary skills and procedures for maintaining the machine. It can be cost-effective in the long term, as there is no need to pay for professional services regularly. Conducting maintenance in-house also allows for more flexibility, as maintenance can be done at any time without having to schedule appointments.

The downside of conducting maintenance in-house is that it requires time and resources to train personnel in the necessary skills. It may also be challenging to diagnose and repair complex issues without the necessary expertise, which may lead to further damage to the machine.

China Skid Steer Loaders: Conclusion

Regular maintenance is critical to the safe and efficient operation of China Skid Steer Loaders. By adhering to a maintenance schedule, operators can identify and address potential issues before they become major problems. This approach not only increases the lifespan of the machine but also improves its overall performance and reduces operating costs.

Common maintenance issues, such as overheating and hydraulic leaks, can be addressed through routine maintenance tasks like fluid checks and filter replacements. Maintenance can be conducted either in-house or by hiring a professional, but either way, it should be an ongoing priority for any operator of a skid steer loader.